To be one of the world’s premier engineering and project management organization with extraordinary results while creating satisfying careers for our people.

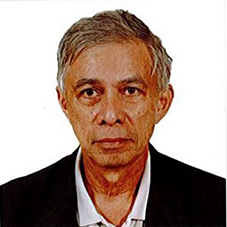

About 6 Sight Studio

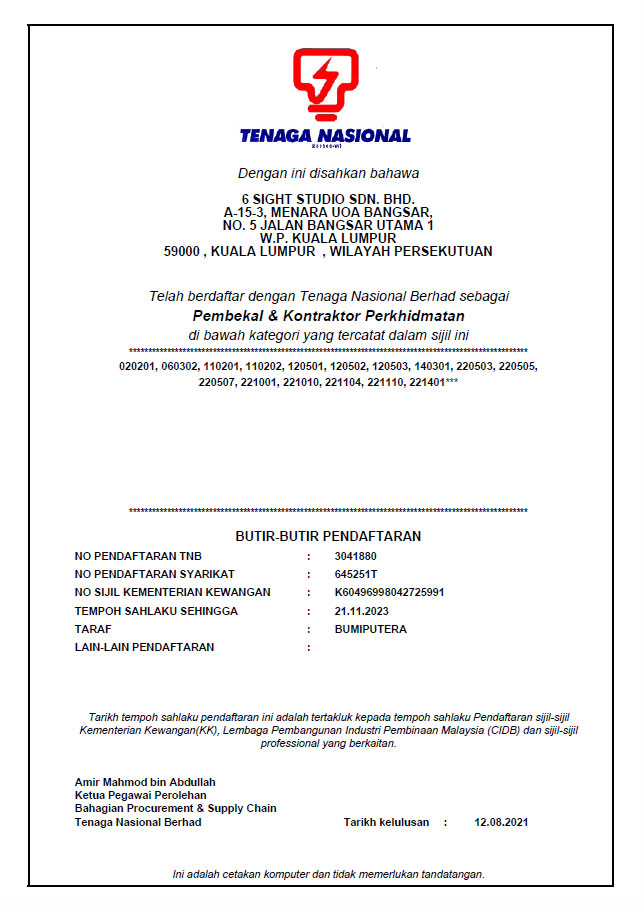

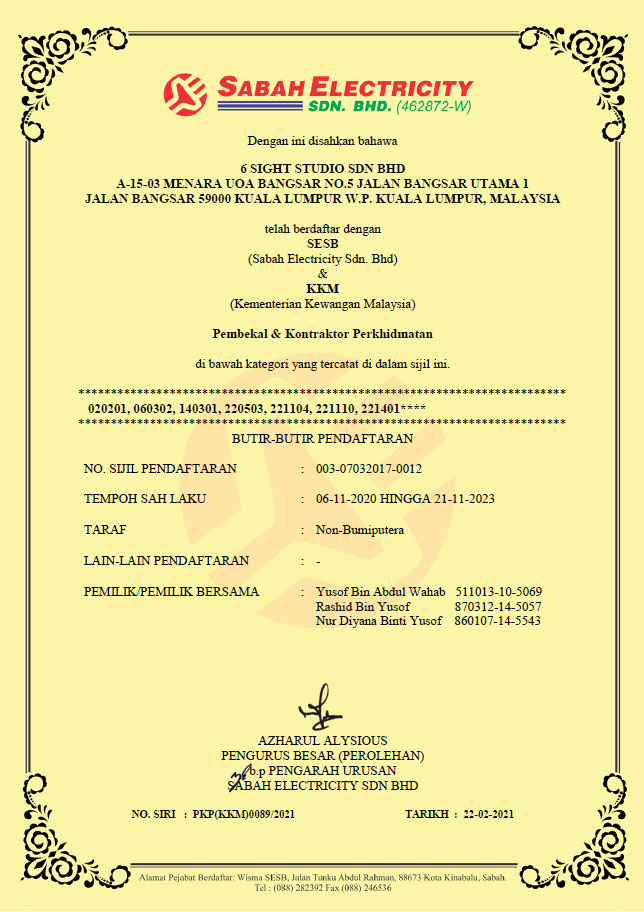

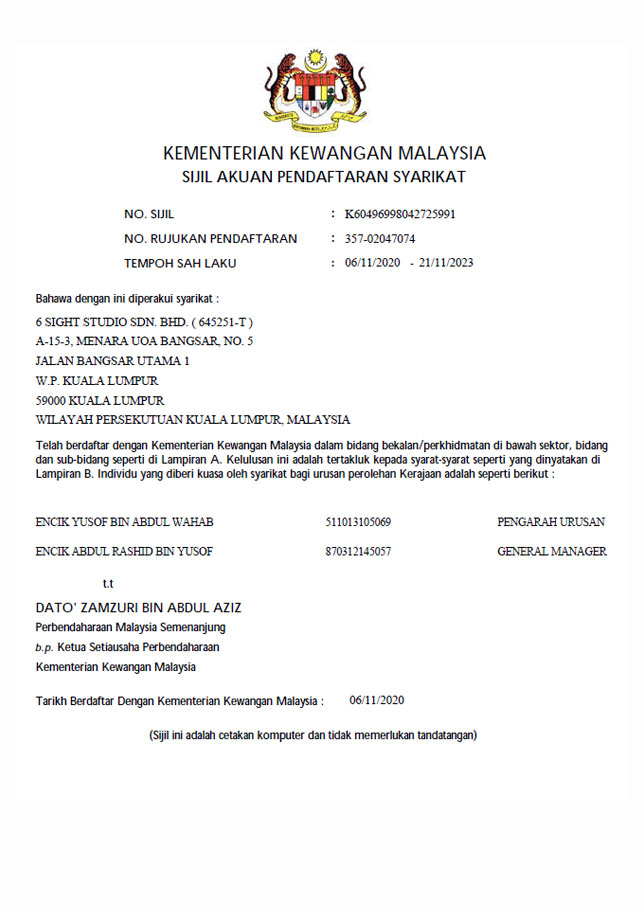

6 SIGHT STUDIO SDN BHD (6SS) was incorporated on 11th March 2004 and has been in operation since September 2017.

6SS is in the business of providing Engineering Services for the Malaysia Electrical Supply Industry (MESI). It holds agencies for Ergon International Inc (transformer insulating oil) and Moser Glaser GC (bushing and busbar). It also collaborates with S&S Power Switchgear Limited India in providing repair, maintenance, overhaul and services for S&S disconnectors. 6SS is also the local agent for several other agencies.

6SS works closely with major power utilities in Malaysia providing high quality products and services.

Our Vision

Our Mission

To deliver world class engineering services and products.

Ethics

We are uncompromising in our integrity, honesty, and fairness.

Safety & Health

We are relentless in keeping people safe from harm, and we provide a healthy work environment.

Quality

We are passionate about excellence and doing our work right the first time. Our reputation depends on our delivered value in the eyes of every customer and community.

Culture

We actively build a diverse, inclusive, and collaborative work environment where all views are welcomed, openness is encouraged, and teamwork and merit are cornerstones of our corporate culture. We are proud of what we do and how we do it—and we enjoy doing it!

Relationships

We build positive, long-term relationships with our customers, joint-venture partners, subcontractors, suppliers, and colleagues that are built on trust, respect, and collaboration.

Innovation

We develop and apply world-class technology. We listen, learn, and seek out the best ideas.

Sustainability

We improve the quality of life in communities where we work by respecting local cultures, engaging local people, and protecting the environment.